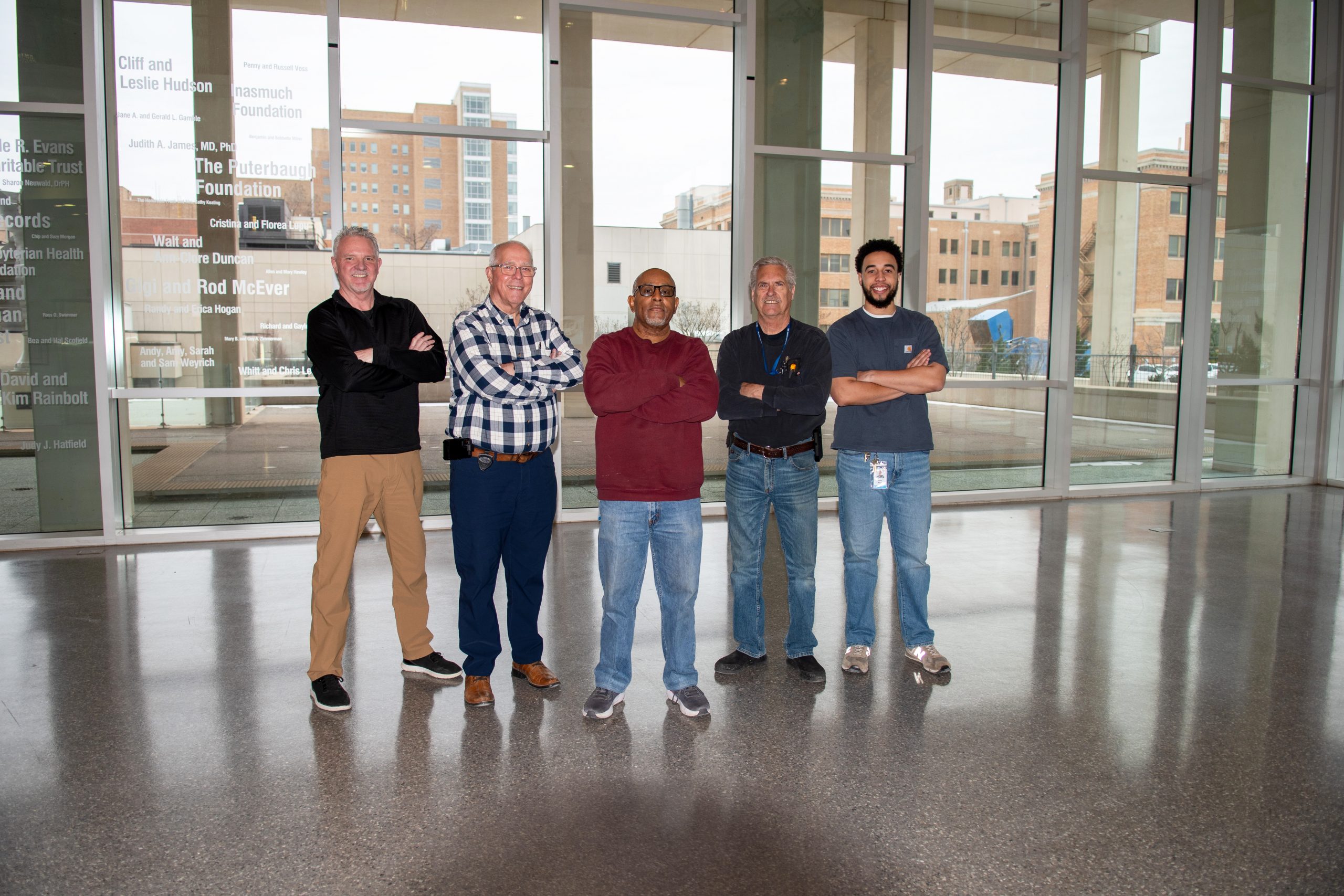

It’s almost unheard of for David Robison and his colleagues to go a full week without at least one after-hours trip to the office. David can’t specify how many late-night or early-morning odysseys he’s made to 825 Northeast 13th Street in his 26 years here. Dozens, maybe?

“Oh no,” he says. “Way more. Hundreds.”

When a critical piece of research equipment needs emergency attention, someone from Scientific Instrument Services rushes into action. Often, it happens on a night or weekend.

Freezers are a common culprit. Nearly 400 are scattered around campus, more than 100 of which reach temperatures of minus-80 degrees Celcius (minus-112 Fahrenheit). Each freezer contains samples critical to past, current and future experiments. As with other expensive lab equipment, they also feature temperature sensors. Any significant temperature rise, and the sensors automatically notify the “SIS” team’s on-call designee. Still, the technology they use for alerts is a bit of a throwback.

“We carry a pager,” says SIS team leader Mike Austin. “Every so often I’ll ask IT if there’s something new that’s more reliable than a pager. There’s nothing yet.”

When Sam Davis drives in to check a freezer, he says his first priority is triage, to ensure the preservation of precious samples. “I’m not doing much diagnostic work. At that point it’s just about moving the contents to a spare freezer, going back home for some sleep and then identifying the same issue the next day.”

The SIS team, formerly known as Biomed, also services an array of other lab equipment beyond freezers – items like incubators and biosafety cabinet hoods. In a typical day, Sam estimates he spends 60% of his work time doing repairs, 30% on preventive maintenance and 10% moving equipment.

The SIS team also inspects and certifies Comparative Medicine equipment annually to ensure OMRF maintains compliance with federal regulations. “Not having to outsource gives us a lot of confidence,” says Jennie Criley, OMRF’s attending veterinarian. “We know and trust these guys.”

During external training sessions and conferences, Davis has discovered that OMRF’s multi-talented team is rare among research institutions. “Most places have specialists – people who only fix freezers and people who only do ventilation.”

Like his SIS co-worker, Jordan Mirich appreciates the opportunity to develop a broad skillset. It adds variety and learning opportunities, such as the refrigeration training he and Rick Billetter will receive this spring.

Count Umesh Deshmukh and Harini Bagavant among the team’s biggest fans. When a pair of 18-wheelers moved their lab from the University of Virginia to OMRF in 2013, SIS unpacked the trucks so quickly that their lab was running at full speed within a week of their arrival in Oklahoma City.

Six years later, as the couple watched a Thunder game, a phone call came bearing bad news. The rising temperature on their ultra-low freezer had sent Pat Marble, then a part of the SIS team (and now services OMRF’s security and IT equipment).

Umesh arrived to find Pat putting the freezer’s contents in a spare freezer, a move that saved 15 years of samples. More recently, Sam replaced a minus-80 compressor, saving Umesh’s lab the $15,000 cost of a new freezer.

“The SIS team has come through for us in a pinch. And if we need them again, I know they’ll be there,” says Umesh. “We’re lucky to have them.”